Italcertifer S.p.A. Laboratories have the skills and all the instrumentation necessary to perform noise tests emitted by vehicles, systems and sub-systems in the railway sector in accordance with the European reference standards.

Laboratory technicians and engineers perform:

- Measures for the assessment of the acoustic pressure level and verification of compliance with the noise limits emitted outside the railway vehicle and defined by the TSI 1304/2014 and ISO 3095 regulations. In accordance with the standard regulations, tests are carried out with the vehicle in the following conditions: parking, starting, and transit at maximum speed. According to the type of test performed, the measurement equipment is positioned at well-defined measurement points.

- Measures for the assessment of the acoustic pressure level and frequency and verification of compliance with the limits of the noise emitted inside the driver's cab of the railway vehicle defined by the TSI 1304/2014 and EN 15892 regulations. In accordance with the standard regulations, tests are carried out with the vehicle in transit at maximum speed and in parking condition while the acoustic warning horns are in operation (evaluation of amplitude and frequency). The measurement instrumentation is positioned near the driver's ear and at well-defined measurement points, based on the type of test performed.

- Measures for the assessment of the acoustic pressure level and frequency and verification of compliance with the limits of the acoustic warning devices (horns) outside the railway vehicle, defined by the TSI 1302/2014 and EN 15153-2 regulations. In accordance with the regulations, tests are carried out with the vehicle parked while the acoustic warning horns are in operation. The measuring instrumentation is positioned in measuring points well defined by the regulations.

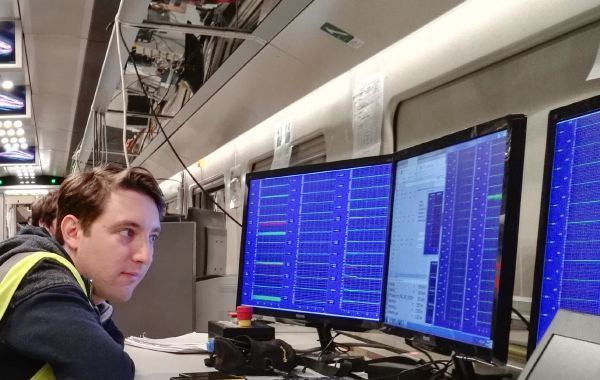

The measurement instrumentation used is in class 1 – calibrators and phonometers (sound level meters) and complies with the provisions of the international reference standard.

Italcertifer Laboratories also carry out both accelerometric measurements on components and vibration measurements in accordance with the provisions of the Italian Law Legislative Decree 81/2008 and the ISO 2631-1 and ISO 5349 Standards.

By means of accelerometric measurements it is possible both to carry out support activities for the design of components, for example the validation of numerical models such as those with finite elements (FEM), and to carry out investigation activities aimed at identifying the causes of possible problems.

The vibration measurements carried out in the field of safety in the workplace contemplate those in the whole body, which occur in cases where vibrations are transmitted to the human body through several points, such as, for example, cabins of railway vehicles (working vehicles and non-working vehicles as well), forklifts, mobile platforms, etc., where the operator can assume different positions (sitting and standing positions).

On the other hand, hand-arm measurements involve the transmission between the human body and the generic machine through handles, steering wheels and joysticks or the interaction with manual tools (screwdrivers, drills, grinders, etc.) and have the effect of generating damage to the muscular system as well as the skeletal apparatus.

All the measurement instrumentation used is subject to periodic calibration and is kept under control by the Italcertifer Laboratory through an adequate metrological confirmation process.