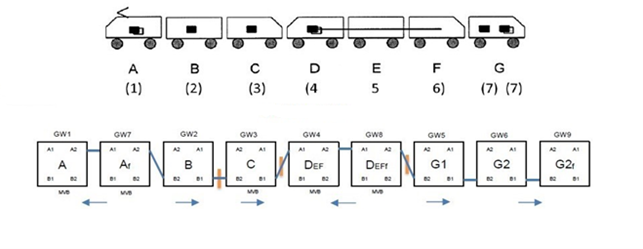

On-Board Technological Systems (or Onboard Subsystems) fall into the category of CCS systems, i.e. Control, Command and Signalling Systems and are classified as Class A Systems (ERTMS/ETCS, European Railway Signalling System) and Class B Systems (SCMT, Sistema di Controllo della Marcia del Treno[1]).

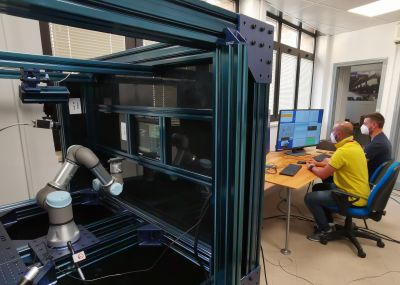

Italcertifer Laboratories have the know-how and instrumentation necessary to perform tests on On-Board Technological Systems and on trackside signalling equipment in the railway sector in accordance with the national and international standards of reference for both classes, in particular:

Tests on on-board technological systems are carried out according to the RFI TC.PATC ST CM 03 E23D specification, in compliance with the requirements of the ANSF decree 1/2016 and according to the TSI CCS. The tests concern all the equipment making up an On-Board Technological System, such as:

- On-Board Subsystem which can be presented in a stand-alone SCMT version, in a version integrated with the SSC functionalities or as a National System module integrated in the SSB ERTMS/ETCS;

- Tests on Radio Cab, voice radio system;

- Tests on RCEC, running behaviour events recorder system.

The Measurements of the Signal to Noise Ratio – an accredited test according to FS Specification no. 371425 esp. 0.0 and according to RFI TC.PATC ST CM 03 E19 C - Paragraph 7.1.2 – are measurements carried out to determine the maximum disturbance allowed on the sensors of the RSC equipment in the SSB SCMT. The electronic equipment and the traction motors installed on board the railway traction vehicles can generate electromagnetic disturbances which, induced on the sensors of the RSC equipment, disturb the regular capture of the codes present on the Ground Sub-System of the national railway lines SCMT. Italcertifer Laboratories are the only ones in the world with AC Tests on ground signaling products (such as LEU or SCMT encoder).